By Indra Jhaveri

Buying second-hand jewelry requires close examination and analysis. It’s important to consider the type and quality of all the gems, metals and manufacturing processes to determine value. Second-hand jewelry shoppers may select those that they like, but if they are truly looking for value when it comes to second-hand shopping, it’s always best to get the professional opinion of a jeweler who has all the proper equipment to make the most accurate appraisal.

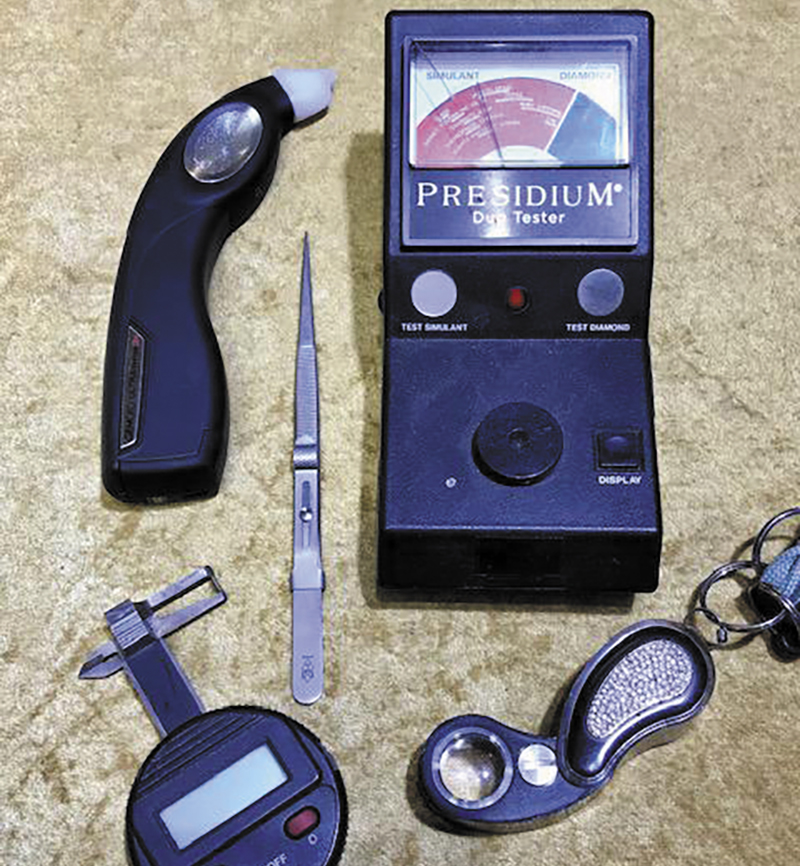

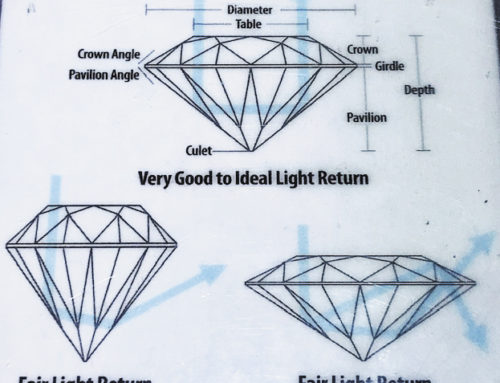

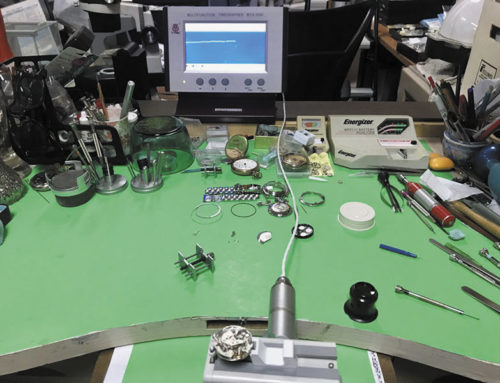

Stones must be identified and metal type determined. Identifying stones requires visual examination using a 10x loupe or microscope and sometimes even the use of a refractometer, polariscope, dichroscope, spectrometer and/or specific gravity liquids. Some specialized equipment exists to help discriminate natural and man-made diamonds, and simulants such as cubic zirconia, moissanite, and even synthetic white sapphires.

There are hundreds if not thousands of materials that can be used in jewelry, and the value of a gem material depends upon material type, color, inclusions in transparent material and the quality of cutting and polishing. Metals used in jewelry are typically alloys, which are are combinations of different types of metal that affect purity, alter appearance and improve workability. The acid test is a classic technique that uses different types of acids to test the reaction of a tiny bit of metal scratched onto a black stone.

Each alloy reacts differently to the various liquids used during testing. Modern metal testing methods include devices that test thermal or electrical conductivity. Generally, Karat gold and sterling silver are used for fine jewelry and base metals or even plastics are used for costume jewelry.

The type and quality of manufacturing is also an important element of value. Some of the finest pieces are entirely hand fabricated and completely unique or even one-of-a-kind. However, most jewelry is fabricated on a larger scale. With the casting technique, a master model is made, a mold is created and then wax is used to create models that are cast in the desired metal.

In the stamping technique, a design is carved into steel. Metal placed into this type of mold is shaped using very high pressure to push the metal into the impression. Both of these methods allow the replication of the same image. Different amounts of hand finishing are required to set stones and polish the final product. These elements of stone and metal types along with manufacturing processes all play into the evaluation of worth and value of a piece of jewelry.

For more, visit www.amidiamondsandjewelry.com, email [email protected] or call 602-923-8200.